Landmarks are applying the potential of Virtual Reality to real-world business challenges.

Industrial machinery is an enormous investment for businesses. Installations are often custom-made for specific purposes; visualising the necessary adaptations to working premises and procedures can be difficult. Ensuring a workforce is properly trained can further delay implementation.

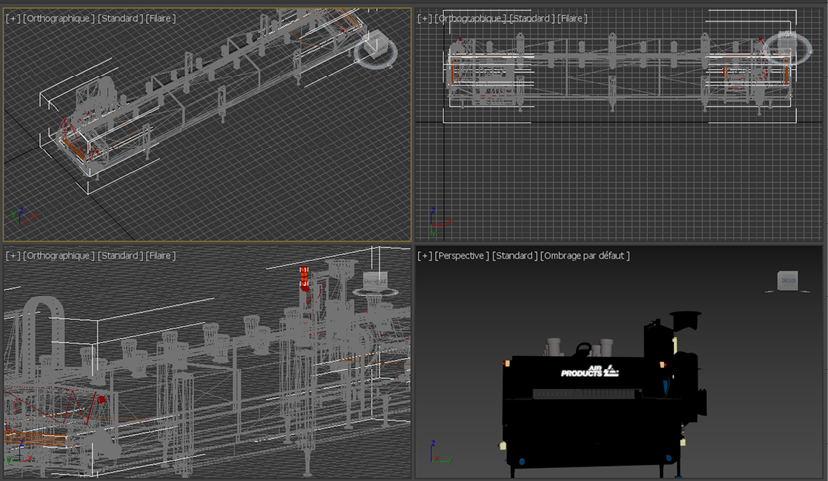

To help Air Products demonstrate the business opportunities afforded by Virtual Reality (VR), Landmarks developed a Freshline® MP Tunnel Freezer in the Metaverse. Through a VR headset, a true immersive and interactive exploration of this industrial installation is possible.

Engineers are able to explore the Freshline® MP Tunnel Freezer simultaneously wherever they are located; travel time, costs, and associated CO2 emissions are eliminated. Training, usually possible only after industrial installation, can be arranged ahead of launch ensuring that production delays are minimised and Air Products’ ambition to be a leader in EHS performance is realised.

Get in touch to discuss how Landmarks can help you.